The installation of the pneumatical transport system for samples, allows the internal tranport of samples, documents and small objects in a quick way, secure and completely automatized.

_It exists two different solutions:

Point to point system

Compuesto por únicamente 2 puntos de envío y recepción.

Multi-point system

Since 2 points up to 100 sending points and reception points, with a capacity of communication of all the points.

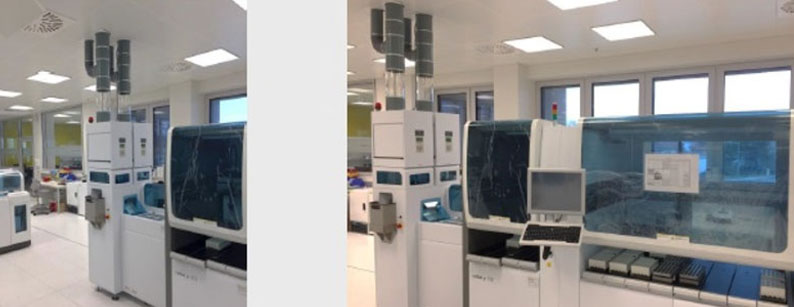

Automatic Unloading Station, Pneumatic Sample Transport.

Pneumatic transport. Automatic laboratory station.

The installation it is composed by a set of points or reception points and sending, fitted strategically in diverse points of the hospital services. The union between the stations is established through a pipe in the interior of which circulates the carrier to transport objects, called cartridge.

According to the number of points to be connected, the systems are divided into independents lines with a capacity of each line of 1000/sending’s day.

The tube net that connects the different stations its formed by a calibrated tube of PVC with diameters of 110 or 160 mm, depending of the type of transports to realize. Regarding the distance, it is possible to realize small distances of some meters and also exceed 1 km between 2 different points.

As an exception of the high capacity lines with direct connection to the transfer, for each line it is possible to move simultaneously only one cartridge in both directions, absorbing direction or blowing direction. In the high capacity lines with direct connection to the transfer we can move simultaneously 5 cartridges in one unique way, reaching an average of productivities of 250 sending’s / hour.

The control system of the installation allowsto visualize de situation of the cartidge in real time, with a control of the duration service, with the register of hour and minute and second of departure and arrival of the cartridge. Additionally allows to realize maintenance functions, and remote access to the elements that perform the installation.

The pneumatical transport system can incorporate in an optional way such an additional functionalities, by the implementation of a RFID chip in the cartridges and an reading/recording aerial in the stations.

Safe shipment of samples

Safe reception of samples

Pneumatic conveying system of samples is simple to implement in both existing buildings and new construction.

With these devices it is possible to register in the RFID chip the following information:

- Direction of origin, destiny and priority of the cartridge.

- Number of sending’s performed with each cartridge, avoiding incidents for breakage of the joints on the inside of the conduction tubes and facilitating at the same time the preventive maintenance.

- Automatized devolution I of the cartridges to their origin station.

- Automatical restore of the installation without the loose of the cartridges.

Additionally, for a control of the traceability of the content to be transported it is possible to read the ID of the item to be transported and register the identification of the user by reading the identification card in the sending and receiving station, in this way there is a total traceability essential for the sending critical samples.

The traceability and security of what was sent, when and who, also when it arrived and who received it is essential and demanded more and more in the facilities.

ARTISTERIL, has over 25 years experience in the implementation of Pneumatic Conveying Systems and Document Samples, with more than 150 installations in operation.

_some of our references

Hospital St. Pölten, Austria

Josef Hospital, Vienna, Austria

Hospital de Bellvitge, Hospital Clínico de Barcelona, Fagor, Hospital Edgardo Rebagliati (Perú-Lima) Liondell Basell, Joyería Suïssa (Andorra), Eurofragance, Conmasa, Hospital Germans Tries i Pujol, Hospital Infanta Sofía, Hospital La Paz, Hospital Virgen Macarena, Hospital Carlos Haya, Dupont Ibérica, Quirón, Media Markt, Hospital San Juan de Dios, Hospital Sousa Martins (Portugal-Guarda), Hospital de Lugo,…